Saltwater will hurt your boat more than any other waters. You need to prepare your boat so much to prevent damages from salt waters. Here’s how saltwater effects boats.

Saltwater damages the metal parts on the boat by corroding and forming rust on the surface (metal) if they aren’t appropriately maintained. Saltwater is highly corrosive, and saltwater corrodes metal 5 times faster than freshwater. So saltwater effects the boat more than any other waters.

However, it is impossible to avoid corrosion altogether, but it is possible to prolong the process with the proper maintenance precautions such as washing the boat and flushing the outboard with fresh water after every ride.

The main effects of saltwater on boats are rust, nothing else, and the rest of the problems are the same as the common problems related to freshwater. Saltwater is highly corrosive, and saltwater corrodes metal 5 times faster than freshwater.

Salt accelerates the rusting process by lowering the electrical resistance of water. Rust happens through a chemical process called oxidation in which metal atoms lose electrons, forming ions. The more efficiently the electrons flow from iron to oxygen, the quicker the metal rusts (source).

Since the boat spends most of the time in the water, so it rusts quickly. But the boat doesn’t rust; only the metal objects that are submerged (immersed) in the water, such as boat engines, will rust quickly in salt water than in freshwater.

However, the metal objects do not have to be completely submerged (immersed) in saltwater for this to happen because increased moisture in the air and salt spray can provide the electrolyte’s cation (positive ions) and anions (negative ions). Humid ocean air causes the metal to corrode 10 times faster than air with normal humidity (source).

And one more thing to note is the corrosion rate depends on the amount of salt content in the water (salinity). High saline water will corrode the metals faster than less saline water.

Check my articles on Is saltwater bad for jet skis (PWCs) and jet boats (opens in a new tab) to prevent all the damages related to saltwater on jet skis and jet boats.

Check my article on How long you can leave the boat in the water (opens in a new tab) to know how long can you leave the boat in the saltwater and growth prevention tips as well.

Parts of the boat that gets affected by saltwater

The affected objects are not only metal parts; there are some others as well. Here are the things that get affected by saltwater in the boat.

- Boat hull (constructed material)

- Outboard or inboard or i/o motor and its parts

- Trim tabs

- Anchor and anchor line

- Bottom paint will wear off or fade out quickly

- Electric hardware and bolts

If you are boating in saltwater, the essential work you need to do to prevent corrosion or any problems related to saltwater is by washing the boat and flushing the outboard properly after completing the ride.

If you don’t store the boat in the water at the marina, you should wash it every time after boating in saltwater to prevent corrosion. Otherwise, if you store the boat at the marina, then you need to take proper care, such as bottom painting the boat and regular checks.

Okay, before looking into those effects, there is a small product out there that removes salt, inhibits corrosion, and breaks apart salt accumulation in your engine’s saltwater cooling system. The essential use of the product is to remove all the salt particles that are stuck on or inside the boat.

That is the Salt-Away (linked to Amazon) or click on the image (image is linked to Amazon).

This product removes all the salt particles that are stuck on the boat, jet ski, PWC, and inside the engine as well, forming a layer of a coat to prevent corrosion in the future. You can connect the mixing unit to the hose and then start spraying on the boat, and you can use this for flushing the engine and inside the engine bay as well.

If you didn’t find that product, an alternative for salt-away is CRC salt terminator (linked to Amazon). Both are good and helps a lot to prevent corrosion by forming a layer of coat on the surface wherever you spray. It breaks down all the salt particles that are stuck on or inside the boat.

NOTE: Generally, all the mixing units will leak all the time (the ones come along with the salt-away or CRC salt products). But first, check the one you got with the product is leaking too much or not. Suppose it is not leaking, then it okay. If it is leaking more, then use some other products like Gilmour Water Soluble Fertilizer Feeder (linked to Amazon) (still, this one leak, but does the work better than others).

1. Boat hull (constructed material)

The boat hull also gets affected by saltwater. But it depends on the type of material with which the boat hull is constructed. Here are a few boat hulls that get affected by salt waters.

Fiberglass boat: Fiberglass boat can fade quickly (high chances) in saltwater. And can form scratches on the boat hull compared promptly to in freshwater (source). Aluminum boat: Aluminum boats will do quite well in the saltwater, but to prevent fouling, you need to use bottom paint to the hull.

Prevention tips

- Apply bottom paint. However, the bottom paint or anti-fouling will fade out quickly in saltwater compared to freshwater, but it gives at least some minimal protection for the boat hull to some extent.

- Wash the hull after every ride. If you don’t have bottom paint on the boat, then you take a hard bristle brush, and you wash the boat thoroughly after every trip to prevent any damages due to saltwater.

Washing the boat with fresh water is the best way to prevent corrosion on the metal surfaces of the boat. Clean the boat with any boat cleaner for better results. If you are boating in salt waters, then you need to clean the boat every time after taking it out of the water.

You need to be careful if you are using a freshwater boat in saltwater. Some hulls are designed to go in rough waters and for offshore boating. Although a freshwater boat can be used in saltwater, you need to careful while using that in salt waters.

2. Outboard or inboard or i/o motor and its parts

Outboard will be the most affected component of the boat due to saltwater because more than half of the outboard motor is submerged in the water. And many moving components of the outboard motor are coated with a lubricant to prevent any damages. Over time, saltwater depletes those lubricant coating and leaves the moving parts vulnerable to damage.

Many parts of the outboard motor will get affected by saltwater, such as propellers, lower units, anodes, mounting brackets, etc. You can prevent all those effects of saltwater by taking proper care of them regularly.

Prevention tips

Below I gave some tips for cleaning the outboard motor. The same thing applies to inboard and sterndrives as well.

- Generally, there will be holes at the bottom of the outboard motor, just above the propeller (and these holes may vary from the motor to motor). You need to keep the air muffs over them and connect it to the water pipe (hose) and start pumping the water. There will be flush ports for some other motor so that you can connect your hose directly to it.

- The water will go inside the motor, and it will clean the inner walls with fresh water. After starting the process, leave it for 10 min. So, it will clean the inner walls properly. While pumping the water, don’t forget to start the outboard motor before pumping the water.

- It is essential to flush the outboard motor with fresh water after every use if you are using the boat in saltwater.

- After flushing the outboard motor, use any cleaning liquid or any boat cleaner and clean the outboard motor, then open the cowling of the outboard motor and spray lubricant (WD-40 or any other) over the moving parts.

- Doing all those steps (washing, cleaning the outboard, and applying lubricant over it) will prevent the metal parts from corroding and forming rust.

However, it is impossible to avoid corrosion altogether, but it is possible to prolong the process with the proper maintenance precautions after every ride.

3. Trim tabs

Trim tabs on a boat will corrode due to saltwater such as corrosion of the rivets on hinges and relay on the hydraulic press fail due to seawater and corrosion. Sometimes actuators may leak, causing the whole hydraulic pump or electric motor to rust and stop working.

Saltwater corrodes metal 5 times faster than freshwater. So you need to take proper care of trim tabs as well (if you have one).

Prevention tips

The only way to prevent corrosion on trim tabs is by washing and cleaning the trim tabs properly after taking the boat out of the water and then applying the lube over it. So, by applying the lubricant, it won’t corrode quickly.

4. Anchor and anchor line

Boat anchors and anchor lines are other essential things for the boat, and they are made up of metal (anchors and chains), which will corrode over time. If you are using the boat means most probably you will use an anchor for anchoring the boat.

And anchors will be set at the bottom of the water (meaning anchors will be submerged entirely in the water), which can increase the corrosion on the metal by forming rust on the metal’s surface. So, without proper care, these anchors will corrode quickly than any other parts of the boat.

And anchor lines are connected to the anchor, which will be submerged entirely in the water as well. If you are using chains, then it will corrode. Otherwise, if you are using ropes instead of chains, it will wear off quickly. So, you need to take proper care of anchor lines as well, not only the anchor.

Prevention tips

These tips are not anchor ropes; it’s for anchor chains (metal).

- By painting the anchor and anchor line with marine paints. Generally, painting the anchors and anchor lines with marine paints will be seen on big ships, not on small ships (normal boats). However, it eventually wears off, but it offers a substantial amount of protection for some time.

- By galvanizing the anchor and anchor line. Galvanizing the anchor and anchor lines (coating the anchor and anchor lines with zinc) is one of the things many people do to prevent corrosion. However, it eventually wears off, but it offers a substantial amount of protection for some time.

Those two are essential things to do to your anchor and anchor lines to prevent corrosion. But there is one more thing to do, that is washing and cleaning the anchor and anchor lines after taking out of the water. Without washing the anchor and anchor lines, they will corrode even though if you use marine paint or galvanize them.

So, wash and clean them properly after taking out of the water to prevent corrosion over time.

5. Bottom paint will wear off or fade out quickly

Bottom paint will fade out or wear off quickly in salt water than in freshwater, even though if you are using a good quality anti-fouling paint. Still, the bottom paint will do a good job, acting as a barrier between the boat hull and saltwater.

But in freshwater, the paint will take some more time to fade off or wear off from the hull than in saltwater. Since you are boating in saltwater, you need to use anti-fouling paint that is used for saltwater purposes, not the one that is used for freshwater purposes.

Prevention tips

To prevent (to some extent, not entirely), the bottom wearing off or fading out in saltwater is washing and cleaning the boat every time after taking out of the water. Still, it can wear off, but washing will extend the bottom paint life to some extent.

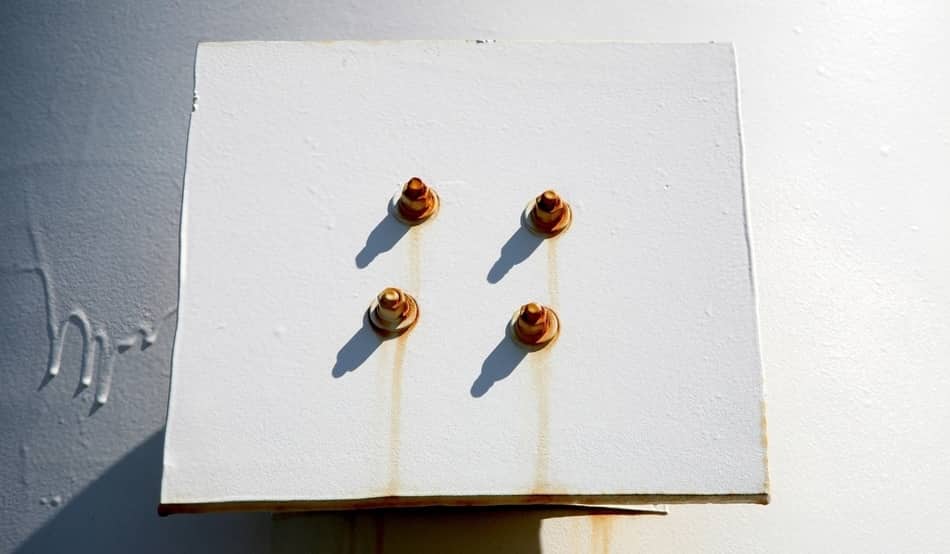

6. Electric hardware and bolts

Electronic hardware and bolts will get affected by saltwater. Make sure that all the wires are kept out of the saltwater. Bolts are also made up of metals that will corrode if exposed to saltwater for an extended period of time. Bolts will form brown color stains on the boat (see the picture above) on the surface. So, you need to clean them often to prevent that.

Prevention tips

- For electric hardware. Try to keep all the electric hardware at a far distance from the saltwater and use any lubricant to prevent damage. Otherwise, use marine graded electronic hardware.

- For Bolts. To prevent corrosion on the bolts, apply lubricant or grease regularly. Saltwater corrodes metal 5 times faster than freshwater. So, you need to be careful with all the metal parts on the boat.

Corrosion prevention tip

Using a lubricant to coat the outer layer of the metals to prevent corrosion is one of the best ways to prolong the whole process. Since you are using a boat in saltwater, WD-40 may not work well. WD-40 will work well for normal (fresh or non-alkaline) waters.

The best lubricant for boating in salt water to prevent corrosion is CRC Heavy Duty Corrosion Inhibitor. It can be used on electrical connections, engine components, equipment storage, fasteners, motors, shaft, spindles, steering, and throttle linkages.

The image is linked to Amazon or click here (linked to Amazon). You can get the product on Amazon as well.

CRC corrosion inhibitor will coat a thick layer of lubricant on the surface where you spray so that it lasts long and essentially works well for salt-water uses. Finally, coat all the metal surfaces with CRC to prevent corrosion over time if you are leaving the boat for a long time.

Bottom line

Saltwater is not good for boats because it corrodes the boat forming rust on the metal surfaces of the boat. Saltwater corrodes metal 5 times faster than freshwater. So, you need to be careful while boating in saltwater.

Humid ocean air causes the metal to corrode 10 times faster than air with normal humidity. The only best way to prevent corrosion due to saltwater is to wash the boat with fresh water every time after removing the boat out of the water. By doing that, all the salt particles on the boat will get eliminated.